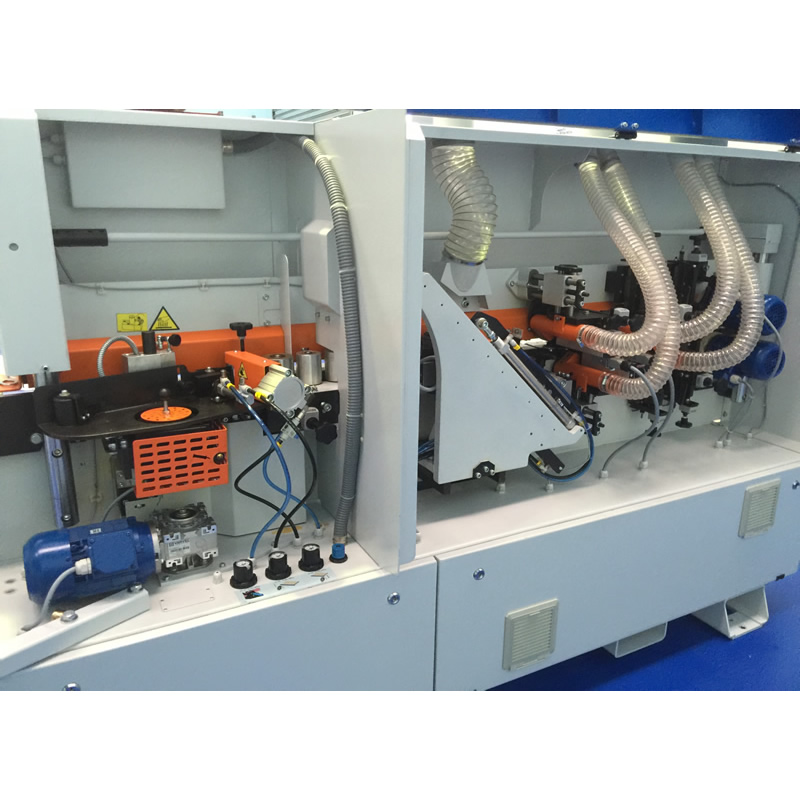

Edgebander NikMann-TM series

Automated and Affordable

Designed for Australia - Made in Europe

Simply the best

WORKING UNITS

| NikMann TM | Functions |

| # Exchangeable Teflon glue tank with electronic regulation of the glue temperature and automatic lowering the temperature of the glue at recess. |  |

| # Heavy duty guillotine for preliminary cutting of thick PVC /ABS /Veneer edges with 3 big positive pressure rollers. |  |

| # End trim saws on NikMann edgebanding machines have two motors. |  |

| # Top and bottom trimmers with vertical and horizontal adjustment equipped with Nesting Kit for hinge holes /optional/. |  |

| # Set of round scrapers |  |

| # Set of glue scrapers. |  |

| # Set of buffing wheels to polish and clean the tape |  |

SPECIFICATIONS

| Model | NikMann TM |

| Panel Length: |

≥100 mm |

| Panel Width: |

≥100 mm |

| Panel Thickness: |

8~60 mm |

| Edge Thickness |

0.4~3 mm |

| Feed Speed: |

10 m/min |

| Power: |

6.0 kw |

| Voltage: |

400v AC |

| Compressed Air Pressure: |

6.5 Bar |

| Average Air Consumption: |

110 l/min |

| Overall Dimensions: |

3420 × 1220 × 1300 mm |

| Weight: | 910kg |

| For Price | Call 1300 436 792 |

KEY FEATURES

# One safety door with large windows and internal light;

# Convenient digital screen;

# Manual change set-up from 0.4mm,1mm, 2mm edge thickness with digital indicators;

# Exchangeable Teflon glue tank with electronic regulation of the glue temperature and automatic lowering the temperature of the glue at recess;

# Hinge hole kit for top trimer, round and glue scraper;

# Large 200mm dust exhaust for efficient extraction;

# 3 x independent pressure rollers equipped with digital servo motor driven by PLC control;

# Digital screen motorized height setting on top beam with height pre-sets and tape counting;

# Diamond tipped 60mm diameter cutterheads twin spindle pre-milling station, 45/60 mm high;

# High precision linear bearings on cut-off saws;

# Efficient inverter-controlled motors on saws and trimmers;

# High precision ‘THK’ slide ways on cut-off saws;

# Efficient high frequency direct drive motors on saws and trimmers;

# Blowers on scrape tracer wheels keep swarf from affecting accuracy;

# 1500rpm motors on buffing wheels to prevent scorching;

# Heavy weight machine;

DIGITAL CONTROLL

# The NikMann edgebanders are equipped with electronic control, complete with PLC to carry out quickly and easy program execution.# The NikMann controls the pneumatic and set-up positioning of the operating groups and the automatic start-up of the motors.

# The NikMann controls the 1st to 2nd pass and rounding function, plus the pressure beam position, glue pot temperature, actual motor position, used tape length, more or less control everything.

# All edge banding machines equipped with an electronic control has a graphic display, and controls the rapid selection of the working units too.

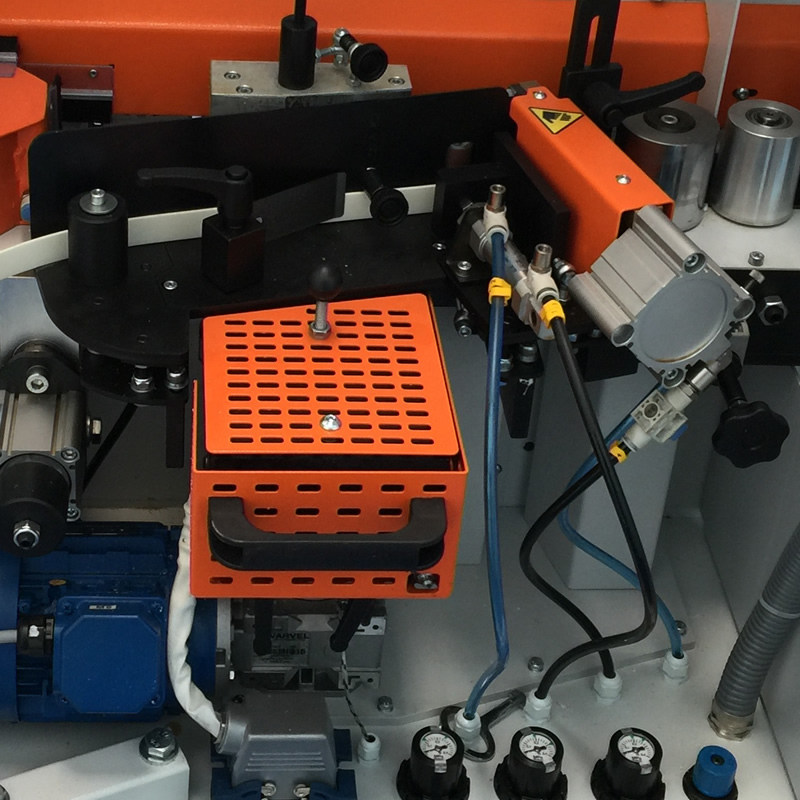

GLUEING UNIT, LOADING AND PRESSURE OF EDGE

# NikMann edgebanders are equipped with a Teflon, Quick heating glue pot for hot melted glue.# Rapid release system for fast glue pot removal.

# Manual exclusion from the working line to enable set up runs or processing without glue application. Teflon-coated glue pot.

# Checking of temperature on the spreading roller and on the main glue pot. Automatic lowering of the temperature to avoid over heating of the glue.

# Spreading roller with device for adjustment of the quantity of glue.

# Automatic strip feeding material in rolls. Heavy duty guillotine for cutting of coiled edges up to 3 mm.

# Coil-holder plate of large diameter 600mm. Pressure rollers with independent spring adjustment and are automatically positioned by the control to the dimension set in the program.

# Powered, fractioned first pressure roller with large dimensions and timed intervention.

# The second & third idle rollers which are tilted, one at the top and one at the bottom with timed intervention to ensure maximum pressure on the top and bottom edge.

END CUTTING UNIT

# Two high frequency /12,000 rpm/ independent motors to cut the front and rear edges.# High precision and heavy-duty end cutting unit with the movement of the two motors on prismatic guide ways with preloaded recirculating ball bearings.

# Each operating motor is equipped with copying device for an accurate positioning of blades in relation to the cutting point.

# The motor operation is timed to prevent chipping on the panel, and the height adjustment to allow the correct tool positioning on the panel.

# The saws can also be tilted to 15 degrees if a bevel trim is required.

# The end saws are mounted on a super strong cast base and run on the same high precision THK guide for perfect alignment.

FINE TRIMMING UNIT

# Two high frequency motors for trimming and rounding of the edges.# Vertical copying device with large rotating disc and hinge hole kit on a top motor.

# Front copying device with 2 rotating bearings.

# All the copying disks have ground contact surfaces to ensure the high precision of the trimming units.

# Fully automated digital motor for the adjustment.

#Device for rapid removal of the cutter’s Automatic exclusion of unit.

#Rapid release of motors both electrical and mechanical.

#NikMann edgebanders are equipped with Nesting hinge hole kit.

EDGE SCRAPING UNITS

# The unit is mounted on a robust column which is fixed to the base of the machine.# Vertical copying device with rotating disc and hinge hole kit on a top.

# Front copying devices with rotating bearings.

# Quick automatic change set-up for easy positioning of various tapes driven by servo motors.

# Exhaust outlets.

#Please note: this unit is nesting compatible

#All edgebanders from Nikmann are equipped with glue scraping unit for the finishing of plastic material for both PVC and ABS edges.

#The machine is equipped with a spray mist unit to improve the panel cleaning and polishing of the edge applied.

#The brushing unit has two motors for the cleaning and polishing of the edges and has horizontal and vertical tilt able motors.

RELATED PRODUCTS

Request Further Information

Sales & ServiceCall us Today:Phone: 1300 436 792 |

ShowroomUnit 9,23-25 Sharnet Circuit, Pakenham, Vic, 3810 |

Trading HoursMonday to Friday: 8.30am – 4:30pmVisit Office: By appointment only. Sunday : Closed |