Edgebanders NikMann-2RTF series

Automated and Affordable

Designed for Australia - Made in Europe

Simply the best

WORKING UNITS

| Edgebanders NikMann-2RTF | Functions |

| # Spraying System - prevents the adhesion of emerging glue onto the workpiece /optional/ |  |

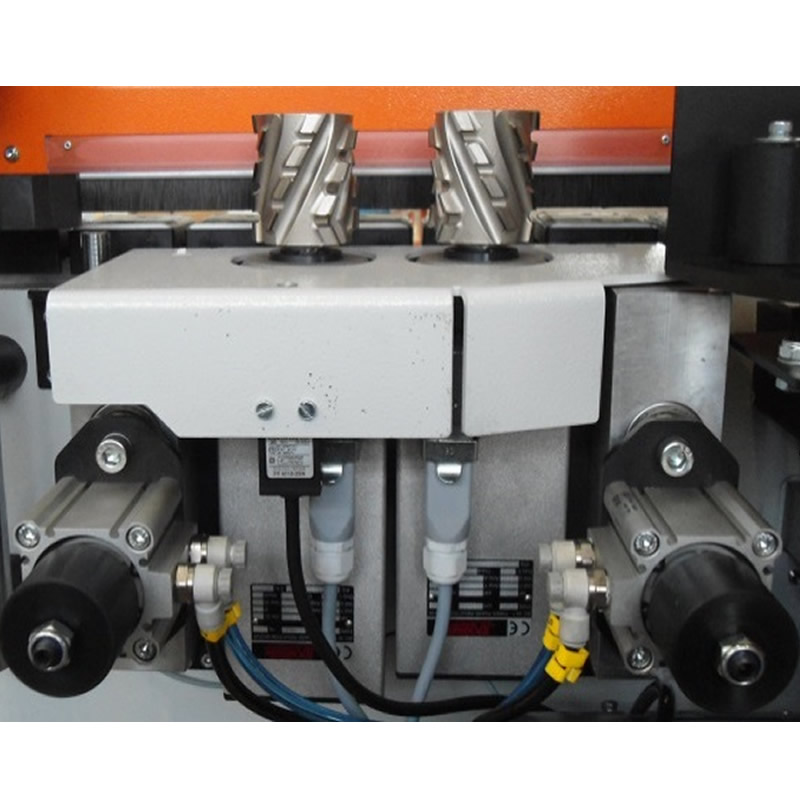

| # Pre-milling unit with 2 separate cutters for perfect finish on a panel surface. |  |

| # Infra red Panel Edge Heating. Pumps heat into your Panel Edges on cold days. Electronic timed activation through the PLC control. |  |

| # Quick-change Teflon glue tank with electronic regulation of the glue temperature and automatic lowering the temperature of the glue at recess. |  |

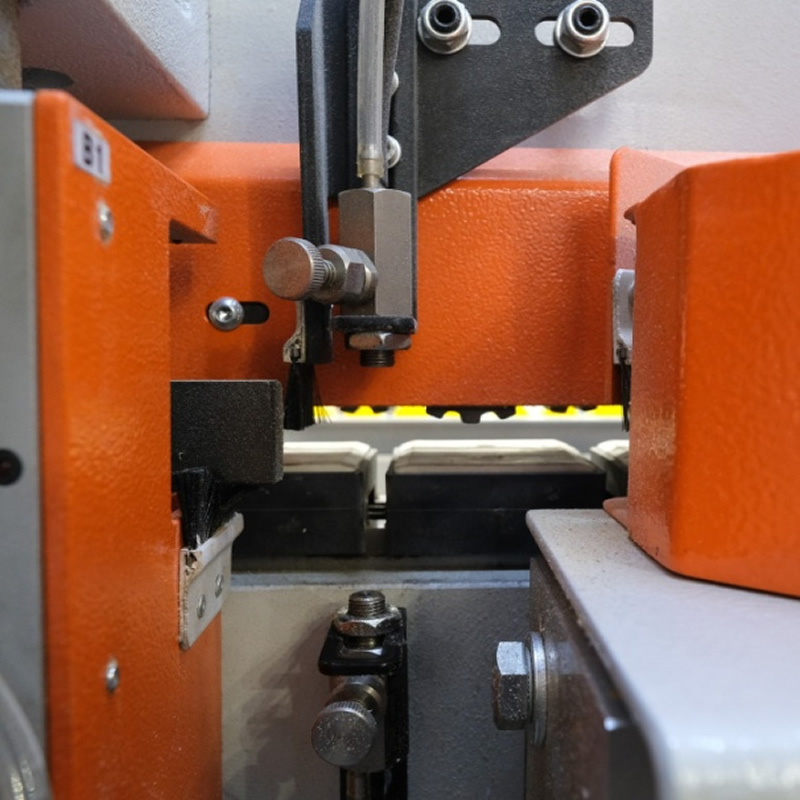

| # Heavy duty guillotine for preliminary cutting of thick PVC /ABS /Veneer edges with 3 big positive pressure rollers. |  |

| # Two End Trim Saws on NikMann edgebanding machines equiped HF motors. |  |

| # Top and Bottom Fine Trimmers with vertical and horizontal adjustment equipped with Nesting Kit for hinge holes. |  |

| # 2 x Corner Rounding Units |  |

| # Set of Round Scrapers equipped with Nesting Kit for hinge holes. |  |

| # Set of Glue Scrapers equipped with Nesting Kit for hinge holes. |  |

| # Spraying System - removal of released agent and loose glue residue. Matt radius of the machined edgeband re-matches the surface finish. /optional/ |  |

| # Set of Buffing Wheels to polish and clean the tape. |  |

SPECIFICATIONS

| Model | NikMann-2RTF |

| Panel Length: |

≥100 mm |

| Panel Width: |

≥100 mm |

| Panel Thickness: |

10~60 mm |

| Edge Thickness: |

0.4~3.0 mm |

| Feed Speed: |

10 - 16 m/min |

| Return Conveyor: |

Optional |

| Dust Extractor: |

Optional |

| Controller: |

Touch Screen - 10 inch |

| Power: |

12.0 kw |

| Voltage: |

400 v AC |

| Average Air Consumption: |

200 l/min |

| Compressed Air Pressure: |

6.5 Bar |

| Overall Dimensions: |

5500 × 1440 × 1730 mm |

| Weight: | 1500 kg |

| For Price | Call 1300 436 792 |

KEY FEATURES

# Three full safety doors with large windows and internal lights;

# Convenient 10 inch touch screen;

# Manual change set-up from 0.4mm,1mm, 2mm edge thickness with digital indicators;

# Exchangeable Teflon glue tank with electronic regulation of the glue temperature and automatic lowering the temperature of the glue at recess;

# Hinge hole kit for top trimer, round and glue scraper;

# Large 200mm dust exhaust for efficient extraction;

# 3 x independent pressure rollers equipped with digital servo motor driven by PLC control;

# Touch screen motorized height setting on top beam with height pre-sets and tape counting;

# Diamond tipped 60mm diameter cutterheads twin spindle pre-milling station, 45 mm high;

# High precision linear bearings on cut-off saws;

# Efficient inverter-controlled motors on saws and trimmers;

# High precision ‘THK’ slide ways on cut-off saws;

# Efficient high frequency direct drive motors on saws and trimmers;

# Blowers on scrape tracer wheels keep swarf from affecting accuracy;

# 1500rpm motors on buffing wheels to prevent scorching;

# Heavy weight machine;

# All Spare Parts for NikMann edgebanding machines are available from Forza Machinery office.

DIGITAL CONTROLL

# The NikMann edgebanders are equipped with electronic control, complete with PLC to carry out quickly and easy program execution up to a maximum of 60 working programs.# The PLC controls the pneumatic, set-up positioning of the pressure beam and the automatic start-up of the motors.

# Also the PLC controls the 1-st to 2-nd pass and rounding function, glue pot temperature, actual motor position, used tape length and much more.

# All edge banding machines equipped with an electronic control has a 10" Touch-screen colour graphic display, and controls the rapid selection of the working units too.

SPRAY MIST & PRE-MILLING UNIT

# The edgebander could be equipped with a spray mist unit to prevents the adhesion of emerging glue onto the workpiece;INFRA-RED PANEL EDGE HEATING

# To heat the panels before the glue application. It improves the gluing quality in case of low environmental temperatures. Electronic timed activation through the line control.PRE-MILLING UNIT

# It is positioned before the gluing unit to trim the panel edge and therefore obtain a perfect uniform surface.# The motor operation is timed to prevent chipping on the panel, and the height adjustment to allow the correct tool positioning on the panel.

# The unit carries out the milling of the panel edge with a variable removal by adjusting the infeed fence position. The infeed fence is fitted with a digital servo motor system which automatically sets the fence position according to the program selected on the controller.

# Optimized tool consumption with position adjustment of cutting.Removal up to 3 mm thanks to high frequency motors and 60 mm diameter tool.

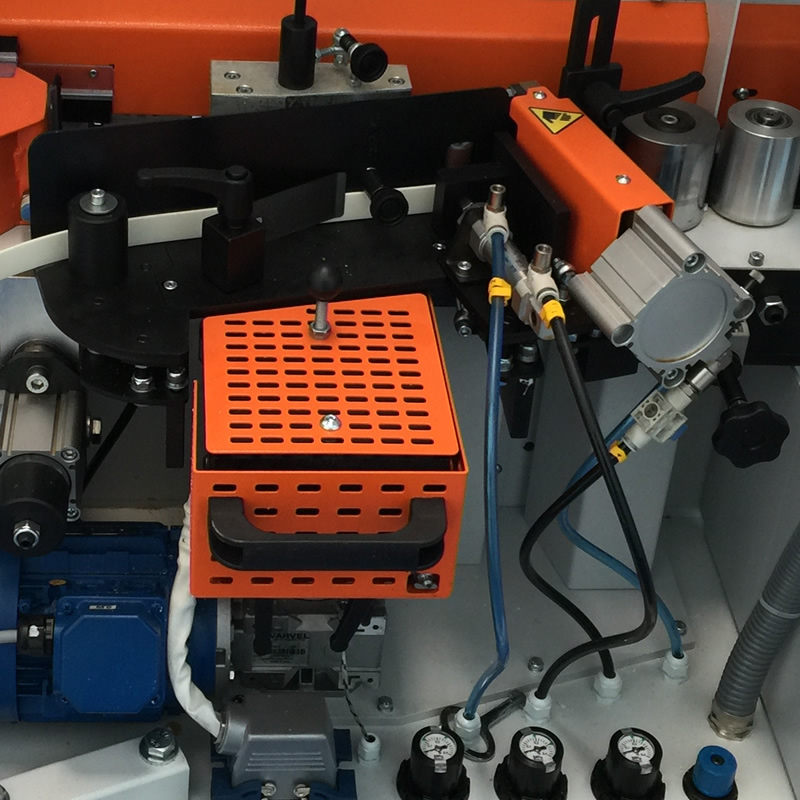

GLUEING UNIT, LOADING AND PRESSURE OF EDGE

# NikMann edgebanders are equipped with a Teflon, Quick heating glue pot for hot melted glue.# Rapid release system for fast glue pot removal.

# Manual exclusion from the working line to enable set up runs or processing without glue application. Teflon-coated glue pot.

# Checking of temperature on the spreading roller and on the main glue pot. Automatic lowering of the temperature to avoid over heating of the glue.

# Spreading roller with device for adjustment of the quantity of glue.

# Automatic strip feeding material in rolls. Heavy duty guillotine for cutting of coiled edges up to 3 mm.

# Coil-holder plate of large diameter 600mm. Pressure rollers with independent spring adjustment and are automatically positioned by the control to the dimension set in the program.

# Powered, fractioned first pressure roller with large dimensions and timed intervention.

# The second & third idle rollers which are tilted, one at the top and one at the bottom with timed intervention to ensure maximum pressure on the top and bottom edge.

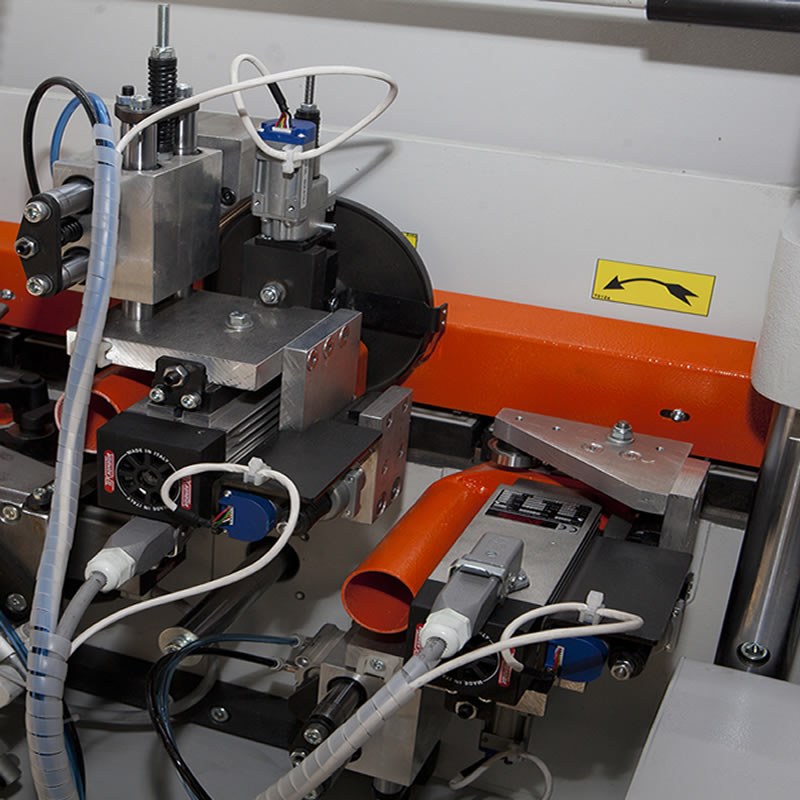

END CUTTING UNIT

# For a perfect cut of the excess edge on the front and rear side of the panel, always guaranteed by a precise and reliable kinematics in all working conditions.# Two high frequency /12,000 rpm/ independent motors to cut the front and rear edges.

# High precision and heavy-duty end cutting unit with the movement of the two motors on prismatic guide ways with preloaded recirculating ball bearings.

# Each operating motor is equipped with copying device for an accurate positioning of blades in relation to the cutting point.

# The motor operation is timed to prevent chipping on the panel, and the height adjustment to allow the correct tool positioning on the panel.

# The saws can also be tilted to 15 degrees if a bevel trim is required.

# The end saws are mounted on a super strong cast base and run on the same high precision linear guide for perfect alignment.

FINE TRIMMING UNIT

# For trimming the excess edge in the upper and lower sides of the panel with a fast and simple machining changeover between thin, thick and solid wood edges.# Vertical copying device with large rotating disc and hinge hole kit on a top motor.

# Front copying device with 2 rotating bearings.

# All the copying disks have ground contact surfaces to ensure the high precision of the trimming units.

# Manual or automatic set up for machining changeover.

# Device for rapid removal of the cutter’s Automatic exclusion of unit.

# Rapid release of motors both electrical and mechanical.

# NikMann edgebanders are equipped with Nesting hinge hole kit.

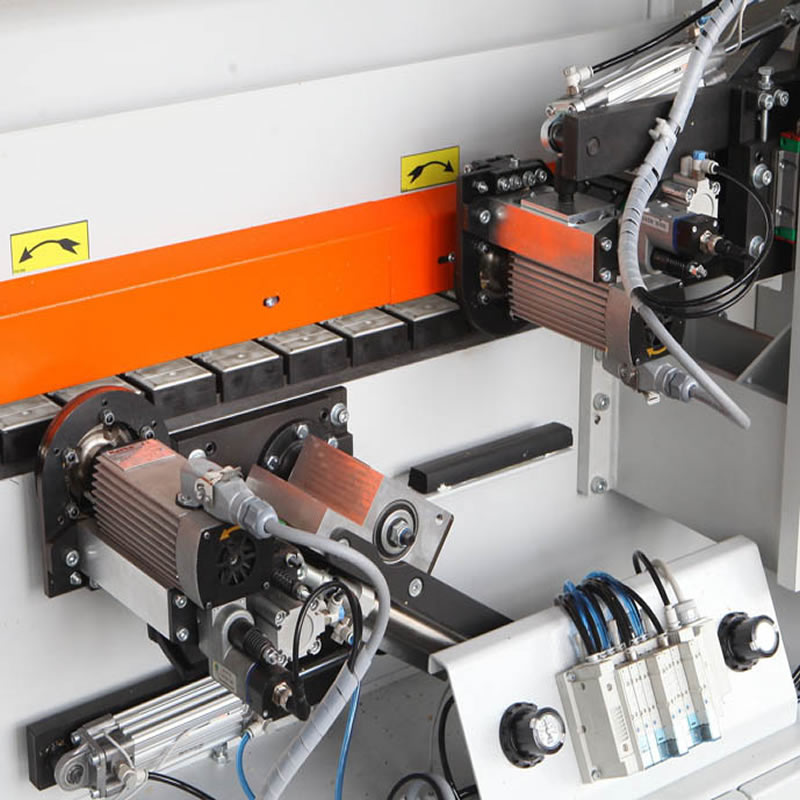

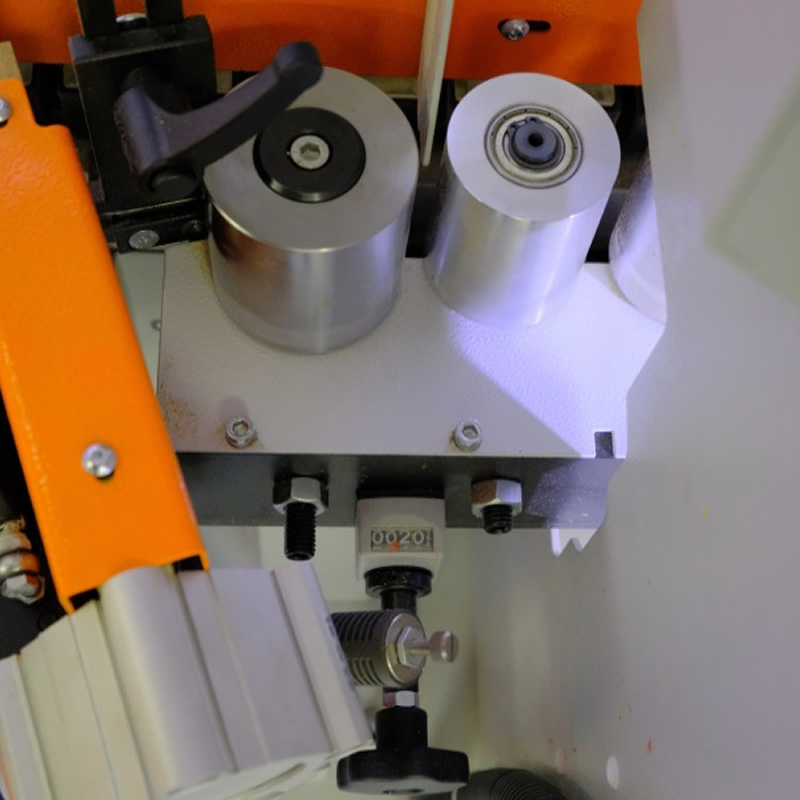

2 CORNER ROUNDING UNITs

# Productivity and Quality with 2-motor technology.# The units will automatic round the applied edge of up to 3 mm PVC or ABS and thin edges applied on straight sides of post/soft formed panels.

# The rounding operation takes place in two single passes and is automatic.

# The corner rounding units on NikMann-2RTF edgebander is complete with a high frequency motors and a front and vertical copying devices which have ground contact surfaces to ensure the best working precision.

# The unit movements are quick and precise on high precision prismatic guide ways with preloaded recirculating ball bearings.

# This units are complete with a manual or fully automated system for quick change between edge tape thickness from the control panel.

EDGE SCRAPING UNITS

# The unit is mounted on a robust column which is fixed to the base of the machine.# Vertical copying device with rotating disc and hinge hole kit on a top.

# Front copying devices with rotating bearings.

# Quick automatic change set-up for easy positioning of various tapes driven by servo motors.

# Exhaust outlets.

# Please note: this unit is nesting compatible

# All edgebanders from Nikmann are equipped with glue scraping unit for the finishing of plastic material for both PVC and ABS edges.

# The machine is equipped with a spray mist unit to improve the panel cleaning and polishing of the edge applied.

# The brushing unit has two motors for the cleaning and polishing of the edges and has horizontal and vertical tilt able motors.

RELATED PRODUCTS

Request Further Information

Sales & ServiceCall us Today:Phone: 1300 436 792 |

ShowroomUnit 9,23-25 Sharnet Circuit, Pakenham, Vic, 3810 |

Trading HoursMonday to Friday: 8.30am – 4:30pmVisit Office: By appointment only. Sunday : Closed |